When working with soldering equipment, safety should be as much a priority as performance. High temperatures, electrical current, and concentrated heat sources can pose risks if the right precautions and properly engineered tools are not used. As a manufacturer committed to safe, reliable electronics-repair equipment, Baku places strong emphasis on designing soldering irons, stations, and heat tools with built-in protections that help users work confidently and securely. Understanding the safety features in the equipment you choose is essential for building a safer and more efficient workspace.

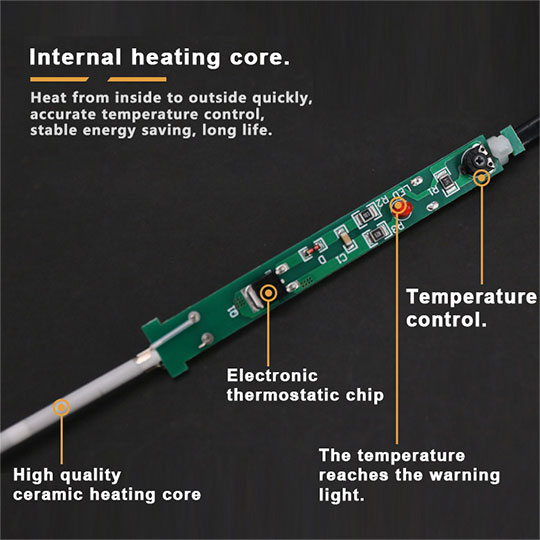

One of the primary safety concerns in soldering is uncontrolled temperature. A soldering iron that spikes too high can burn components, scorch PCBs, or even become a fire hazard. That’s why temperature stability is a core safety element in modern soldering equipment.

Baku’s soldering iron and station lineup is built with intelligent temperature-control systems designed to maintain consistent heat levels. Many models feature overheat protection, automatically regulating the heating element if it begins exceeding safe operational thresholds. This ensures that even during long working sessions, the tool remains within safe limits, reducing the risk of accidental damage or overheating.

Whether you’re repairing smartphones or assembling circuit boards, using equipment with controlled temperature behavior makes your workspace significantly safer.

Hot air tools can deliver intense heat, often ranging from 100°C to over 500°C. Without proper control, that heat can warp components, melt plastics, or cause burns. Baku’s hot air rework stations, including models like the BA-601C+ and others listed on bakutool.com, are engineered with smart airflow control, rapid temperature recovery, and auto-cooling functions that allow the tool to safely wind down after use.

Auto-cooling is a critical safety feature that prevents the heating element from remaining hot after shutdown, reducing both burn risk and wear on internal components. For users who frequently rework SMD chips or connectors, these built-in protections provide stability during high-precision tasks.

A surprising amount of soldering-related accidents come from slips, jerks, or sudden fatigue — especially when holding high-temperature equipment. This is why ergonomics is not just a comfort feature, but a safety requirement.

Baku designs its soldering irons and handles with heat-resistant, anti-slip grips, preventing accidental drops and offering stable control during intricate repairs. Comfortable grip design reduces hand strain during extended work, lowering the chance of a mis-movement that could result in a burn or damaged board.

In addition, Baku’s soldering tools are built with durable insulation materials around heating elements, ensuring that heat stays where it should: at the tip or nozzle, not transferring into the handle.

Though often overlooked, electrostatic discharge (ESD) is a hidden safety risk. A small static shock can instantly destroy delicate chips, but it can also create unexpected sparks in a workspace with metal tools and heated materials.

Many soldering irons and stations in Baku’s catalog are ESD-safe, meaning they are designed to dissipate static electricity safely. This protects your components from latent damage — and helps maintain a stable, hazard-free environment around sensitive electronics.

Any time a hot soldering iron is left on a table, even for a second, the risk level jumps. A stable stand is one of the simplest yet most important pieces of safety equipment — which is why many Baku stations integrate the stand directly into the unit.

This ensures:

Some soldering stations even include rest switches or auto-sleep functions, which lower temperature when the iron is not in use. This minimizes unintended heat exposure and prolongs tip life.

Modern soldering equipment must manage electricity safely, especially in environments where multiple devices run simultaneously. Baku integrates short-circuit protection, over-current protection, and power-management control into many of its soldering stations.

These protections help prevent:

Such features are particularly important in repair shops or training labs, where multiple soldering systems may run at once.

Directing heat precisely is crucial not only for component safety but also for user protection. Baku hot air stations feature interchangeable nozzles designed to focus airflow accurately, preventing unnecessary heat spread and reducing the risk of accidental burns.

Controlled heat flow ensures that only the intended area heats up — a major safety factor for tasks like IC removal, shielding repair, or connector replacement.

While safety glasses, fume extractors, and mats certainly play important roles, the core of soldering safety begins with the equipment itself. Soldering irons and stations designed with fail-safes, thermal protections, smart airflow, and ESD-safe engineering dramatically reduce risks while improving the quality of your work.

At Baku, safety is built into the engineering of every soldering tool we produce. Whether you’re a technician, hobbyist, or electronics manufacturer, choosing the right equipment means choosing a safer, smoother soldering experience.