In the rapidly developing fields of electronics and industrial manufacturing, precision and visibility are essential. As components become smaller and production standards rise, technicians and engineers must be able to inspect and manipulate extremely fine details. Industrial stereo microscopes have become indispensable tools in these environments. With their three-dimensional visualization, high optical clarity, and optional digital integration, they support a wide range of tasks—from electronic repairs to quality assurance in mass production.

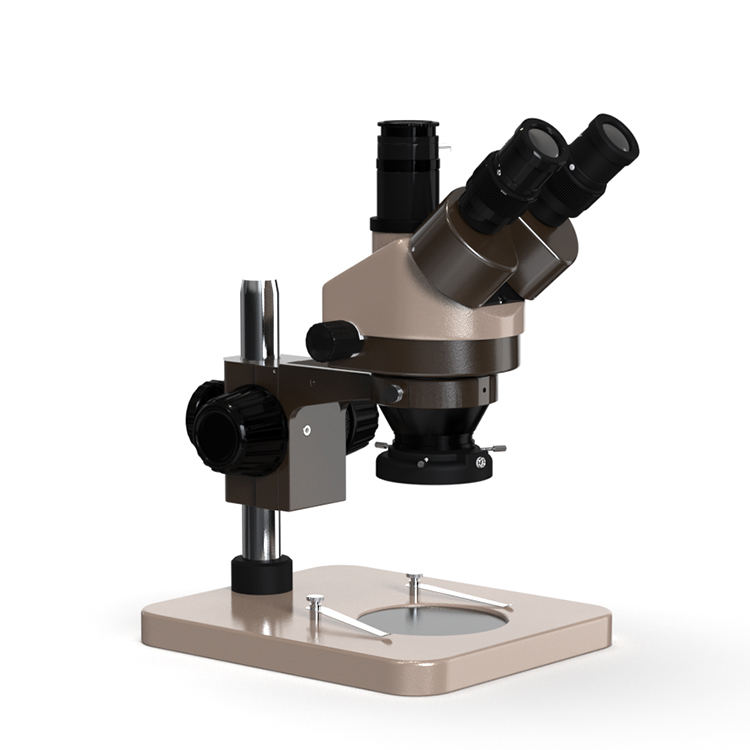

A stereo microscope provides a true 3D view of an object by using two separate optical channels that align with each eye. This depth perception sets it apart from standard digital or compound microscopes and makes it particularly useful for tasks that require precise hand-eye coordination. Many modern industrial stereo microscopes combine optical lenses with built-in digital displays or camera systems, offering both real-time viewing and recording capabilities. These features make them ideal for electronic repair labs, production lines, R&D departments, and manufacturing workshops.

One of the most common uses of stereo microscopes in electronics is during fine-pitch soldering and micro-component rework. As circuit boards incorporate increasingly small components such as SMD chips, BGAs, and IC packages, naked-eye inspection becomes impossible. Stereo microscopes provide magnified, high-contrast views that allow technicians to apply solder with accuracy, inspect the solder flow, and avoid defects such as bridging or insufficient wetting. The 3D depth of field helps operators handle tools and materials without damaging neighboring components.

In electronics manufacturing, quality inspection teams rely on stereo microscopes to examine printed circuit boards. These microscopes help identify missing parts, defective solder joints, micro-cracks, lifted pads, and other production flaws. Because they offer adjustable magnification ranges, inspectors can quickly switch between a broad overview and a detailed examination. Their optical clarity plays an important role in preventing defective products from reaching the next stage of assembly or shipping.

When an electronic device fails, engineers need a reliable way to identify the root cause. Stereo microscopes make it possible to evaluate tiny components, examine alignment issues, and detect hairline fractures or thermal damage. With digital camera integration, teams can capture images or videos for documentation, reporting, or collaborative troubleshooting. This accelerates both repair efficiency and long-term product improvement.

Industries producing micro-mechanical components—such as sensors, miniature connectors, and precision modules—often rely on stereo microscopes during assembly. The 3D visualization allows workers to align moving parts, secure delicate components, and ensure correct tolerances without causing mechanical stress. Adjustable zoom levels enable operators to shift their focus smoothly as the complexity of a component increases.

In robotics manufacturing, accuracy is key. Engineers use stereo microscopes to calibrate small robotic joints, inspect sensor modules, and ensure proper alignment in embedded electronic systems. The stability and magnification range of industrial models make them suitable for repeated calibration tasks throughout the production cycle. When equipped with a digital output, these microscopes also allow teams to monitor and record calibration procedures for future reference.

Stereo microscopes are also widely used in R&D laboratories for examining materials, validating prototype designs, and conducting surface analysis. Engineers rely on magnified, distortion-free imaging to compare samples, test new materials, and refine early-stage prototypes. The ability to quickly switch between different magnification levels helps accelerate product development and ensures higher reliability before mass production begins.

Industrial stereo microscopes offer a number of important benefits that make them suitable for demanding manufacturing environments:

To maximize the value of industrial stereo microscopes, companies should ensure a well-organized setup:

Industrial stereo microscopes play an important role in electronics repair, PCB manufacturing, micro-assembly, robotics, and R&D. Their ability to provide sharp, three-dimensional imaging makes them essential for modern industries where precision is non-negotiable. As electronic and mechanical components continue to shrink in size, stereo microscopes will remain key tools that enable technicians and engineers to deliver higher accuracy, improved quality, and more reliable production outcomes.