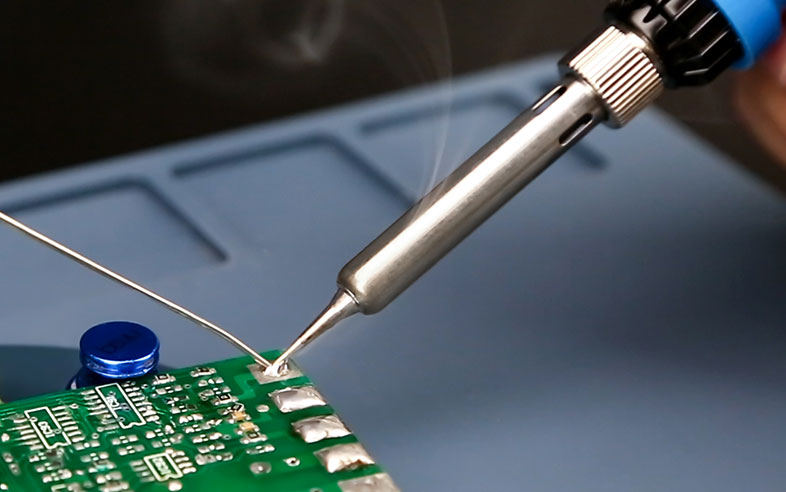

Soldering is a basic skill of electronics work. It is the power to sculpt circuits, the skill to develop and fix the circuits by establishing solid, reliable connections. We learned while studying soldering that in order to produce clean, high-quality solder joints, you need both technique and the right equipment.

To make sure that everyone can go ahead with their own projects as smoothly and efficiently as possible, we’ve compiled a complete list of everything you’ll need to solder with a soldering iron so that you can take tools easily to any electronics job.

The centerpiece of an electronics workbench, a soldering station provides temperature control for more uniform soldering. BK-601D+ Soldering Station, a high-quality digital soldering station, this station features a microprocessor control system and a temperature range of 100–480°C, making it well-suited for soldering and desoldering both surface mount devices (SMDs) and through-hole components. Not only does it feature a compact design, but the digital display also allows users easy access with little expertise required.

A standalone soldering iron is a must for anything small or portable. BA-464 soldering iron, best traditional pen shape soldering iron, ceramic heater; can provide stable heat for your soldering for the PCBs and electronic components soldering. At a 60W output, it’s well-timed for fine, electronic jobs, providing enough heat without burning through anything. You can use interchangeable soldering tips to match to the task at hand, whether you need fine-pointed tips for soldering in close quarters or chisel-shaped tips for wider solder joints.

And not only all around the board, for desoldering and soldering SMD components, you will find it is important to have a hot air gun. The hot air gun handle 942, a portable hot air gun, is a microprocessor controlled device for accurate desoldering of electronic components and soldering of plastic parts. This is flexible for application tasks that need controlled heat with adjustable temperature and airflow settings, and its design for longer and more intensive use. It gives you extreme reliability, providing consistent and stable performance even in a wide range of complex repair tasks.

Solder is the material that creates the electrical and mechanical connection in the soldering process. Such solder wires include BA-100g, with a low melting point (183°C), a fast soldering speed, and can be used in soldering almost all electronic components and circuit boards. These solders provide very good wettability and low melting points, with compliance to environmental standards as well. Flux is also necessary to clean the surface to improve solder fluidity. Our flux products inhibit oxidation during soldering, where the reliability of joints is critical.

You need desoldering products to substitute or fix errors. Our Desoldering wicks BK-1515 and other series are available in a variety of widths for easy use. After wicking, the soldering iron can remove excess solder. A desoldering station have many feature, for example you can use it for more serious desoldering to quickly suck molten solder out. These tools are necessary to maintain a clean work surface and to aid in circuit repairs.

Soldering is one of those things where safety is critical. Repair mats make it easier for you to keep your workspace for repair safe from other accessories, keeping your workspace clean and organized.

In conclusion, our product, such as soldering stations, soldering irons, heat guns, desoldering wicks, and repair mats, has everything you’ll need for your electronics workbench. These devices work well for both hobbyist projects and professional repairs, achieving high-quality results while making safety and reliability a top priority.