In the area of electronics repair and precision soldering, clear, detailed visual inspection is more important than ever. Modern circuit boards continue to shrink in size while increasing in complexity, making traditional magnifying tools insufficient for professional work. A digital microscope for soldering, especially a stereo digital microscope, provides technicians with the high-definition clarity they need to work more accurately and efficiently. From mobile phone repairs to advanced PCB rework, digital microscopes enhance the user’s ability to see, analyze, and perfect every detail.

Digital microscopes offer far superior clarity compared to conventional magnifiers. High-resolution imaging allows technicians to see tiny solder joints, microchips, and PCB traces with exceptional definition. This level of detail is essential when working with micro-soldering tasks, repairing SMD components, or diagnosing faults that are invisible to the naked eye. Clear visuals reduce guesswork, helping operators complete tasks correctly the first time.

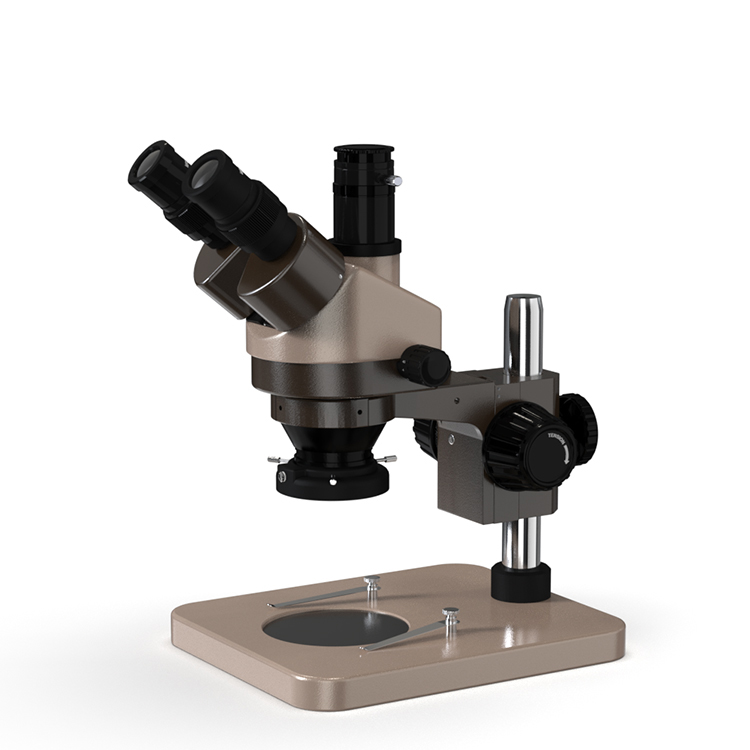

A key advantage of stereo digital microscopes is the added depth perception they provide. Unlike flat 2D images, stereo microscopes offer a three-dimensional view of the work area. This helps technicians judge the distance between the soldering iron and the board more accurately, apply the correct amount of solder, and ensure proper contact between components. Depth perception is especially important for tasks such as BGA rework, solder ball inspection, and fine-pitch component alignment.

Digital microscopes used in soldering often feature adjustable zoom levels to suit both broad inspections and highly detailed viewing. Whether you are checking overall board condition or focusing on microscopic components, the ability to switch magnification quickly improves workflow. Higher magnification models are especially useful for analyzing solder quality, identifying defects, or inspecting extremely small components commonly found in smartphones and wearable devices.

Many modern soldering microscopes offer a magnification range from around 7× up to 150× or more. This flexibility makes them suitable for a wide range of repair applications. For ultra-fine inspection work, some models even reach magnification levels of 600×, enabling technicians to study solder balls, microcracks, and PCB layers in detail.

Digital microscopes often include integrated HD screens that allow users to view the magnified image directly without needing an external monitor. This setup saves space on the workbench and provides a clean, convenient, plug-and-play experience. A sharp, bright display helps reduce eye strain during long repair sessions.

More advanced digital microscopes allow video output to an external display. Technicians can project the magnified image onto a larger monitor for training, group viewing, or detailed analysis. This is also beneficial for documentation, as screenshots and video recordings can be used for quality control or repair reports.

A strong, adjustable bracket is essential for maintaining proper working distance. Digital microscopes designed for soldering typically include flexible stands that allow users to tilt, raise, or lower the microscope as needed. This ensures that the soldering iron, hot air gun, and microscope do not interfere with each other during work.

Some stereo digital microscopes include heat-resistant silicone pads or reinforced bases to protect the equipment from high temperatures. Since soldering often involves hot tips, hot air, and heated components, having a durable, heat-proof working base greatly enhances safety and longevity.

Using a digital microscope for soldering delivers immediate benefits. The ability to see micro-details with clarity reduces the likelihood of errors such as solder bridges, weak joints, and misaligned components. Technicians can identify issues earlier and fix them faster, minimizing rework time and improving overall productivity.

A clear, magnified view also makes delicate operations smoother and more controlled. Whether you are dragging solder across micro-pads, positioning a tiny SMD resistor, or repairing broken traces, improved visibility ensures that each movement is precise and deliberate. It would lead to a cleaner, more professional repair result.

Besides, a digital microscope enhances workflow efficiency. Instead of constantly repositioning lighting or adjusting handheld magnifiers, technicians can work hands-free under stable, consistent illumination. Many users also appreciate the ability to capture images or video for future reference, training, or customer communication.

When selecting a digital microscope for soldering, consider the following factors:

A well-chosen microscope will dramatically enhance your soldering workflow.

A digital microscope for soldering is an essential tool for modern electronics repair. With high-definition imaging, adjustable magnification, stable stands, and advanced display options, digital microscopes distinctly improve both accuracy and efficiency. Whether you are repairing smartphones, reworking PCBs, or performing professional micro-soldering, investing in a high-quality stereo digital microscope will enhance your results and simplify your daily operations.